A tapered drill bit made out of HSS is very hard and resistant to corrosion abrasion and high temperatures. Hex shank drill bits are also available.

Hss Morse Taper Shank Drill Din 345 Rn 20 50 Mm Buy Maykestag Drills Online

Taper type straight shank drill with a TiN coated surface.

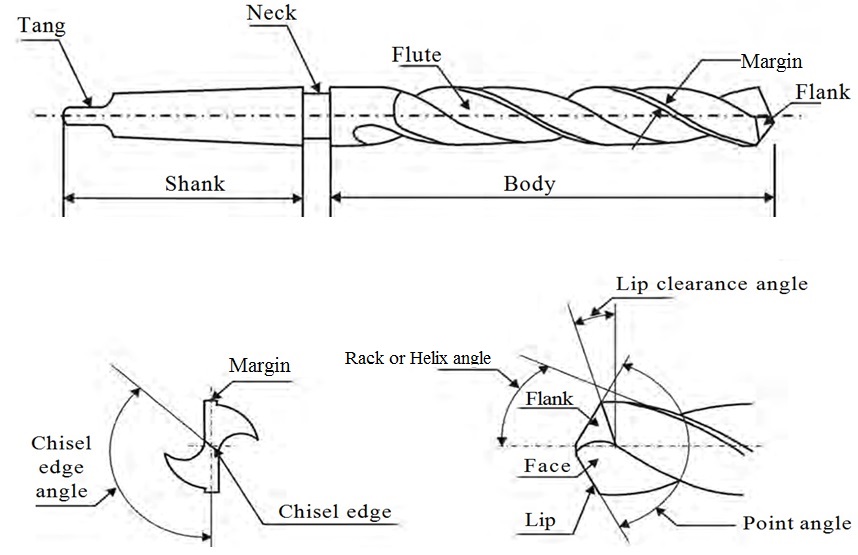

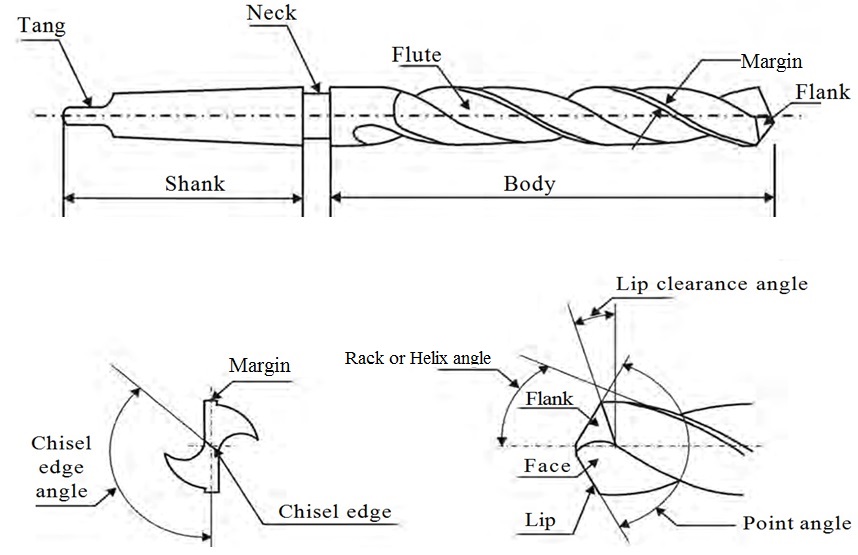

. Morse taper shanks resemble Phillips head screwdriver tips. The shaft is a cylindrical section that terminates in a tapered flat section at one end. Dea Center Lips Heel.

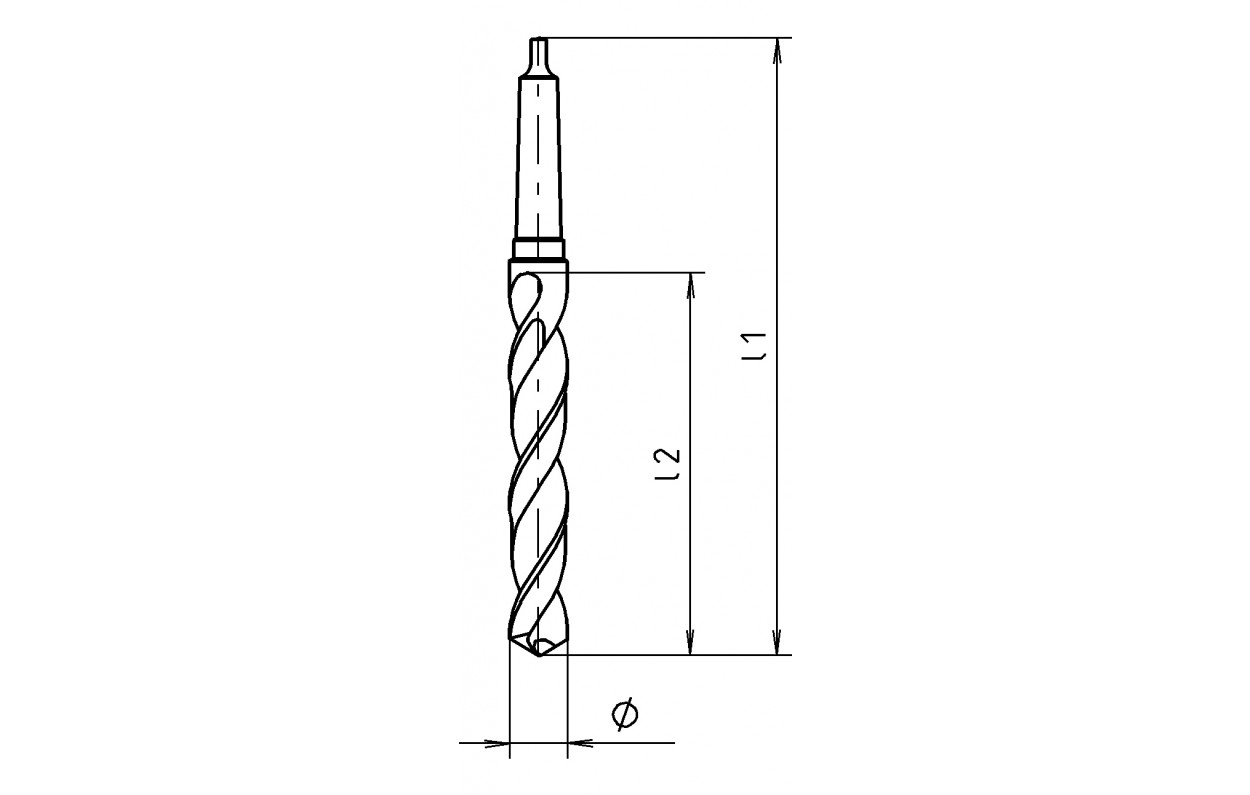

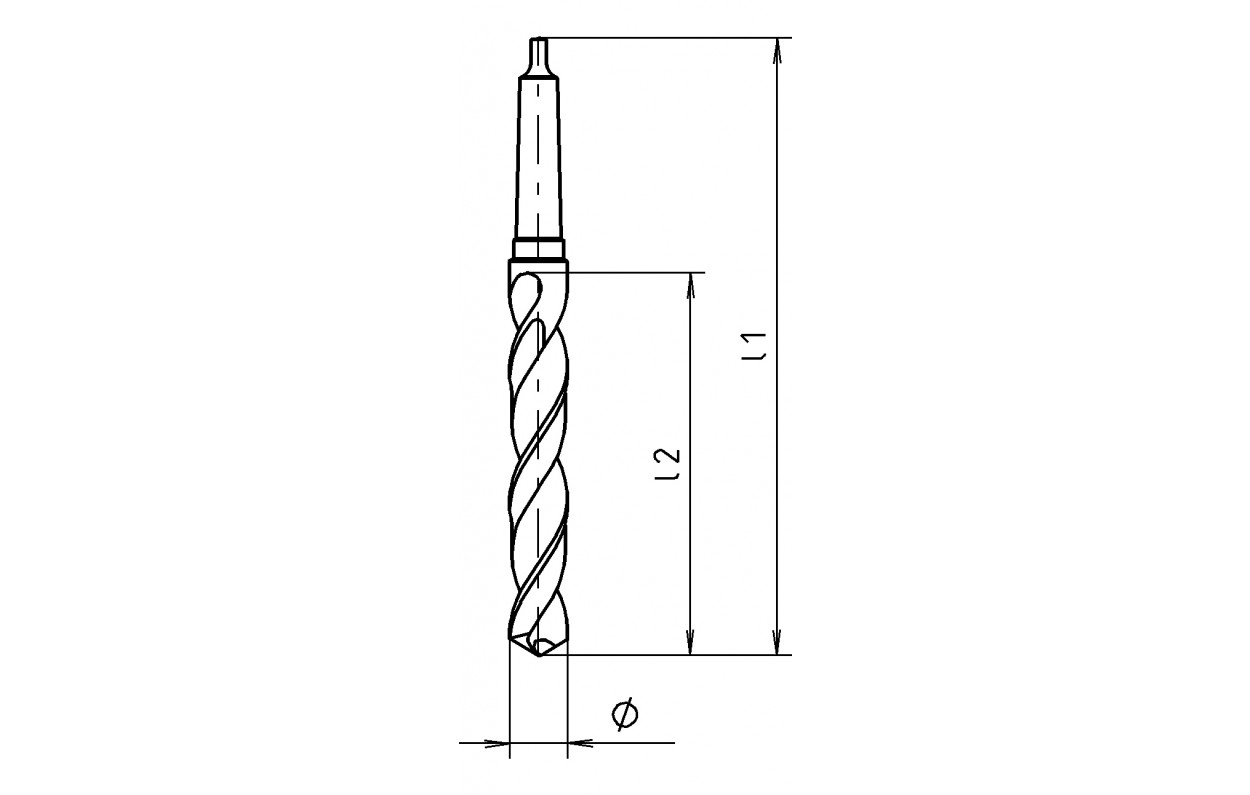

The diameter ranges from 3 to 100 mm. The drills have two helical flutes with a tapered shank for holding and driving the drill. 34 Taper Shank Twist Drill The drills have two helical flutes with a tapered shank for holding and driving the drill.

All machine tapers are sensitive to chips nicks dents and dirt. Taper Shank Twist Drill. It carries a tang at the end of the shank to ensure proper grip between the drill bit and driving machine.

The types of points are Brad Plexi taper Split Screw etc. Install the Morse taper shank directly into the tapered spindle on machines such as drill presses and lathes. The shank for these drills conforms to Morse tapers.

The shank may be straight or tapered. There is provided a tapered drill bit for making straight holes with portable electric drills characterized by having improved features of safety drilling ease speed and utility. A cone-shaped surface formed at the end of the flutes which contains dead center lips and flanks etc.

A taper shank drill high-speed steel is a cutting tool that is attached to a drill press a milling machine a lathe etc. Page 15 Outer diameter Taper mode Applicable drill bit 110 mm 123 mm Morse taper No1 Drill bit taper shank 110 175 mm 127 mm Morse taper No2 Drill bit taper shank 215 mm 143 mm A-taper Taper shank adapter formed A-taper or B-taper 145 mm is. Rotate the bit 180 degrees and repeat.

Morse Taper Shank Dr. For Instance the A dimension for a MT2 female cavity may. The diameter ranges from 3 to 100mm.

And used to drill holes. For technical drawings and 3-D models click on a part number. An HSS tapered drill bit can retain its hardness.

Carbide V Drill Taper Shank for H7. The figure illustrates the drill. TiN coating achieves longer life.

Point is the main part of a drill bit. For more precise more efficient operation. The parallel shanks are provided in small tool bits.

A drill bit shank is the end piece of a drill that connects into the chuck of a spinning mandrel. Hss Taper Shank Twist Drills For Deel Hole Drill Find Complete Details about Hss Taper Shank Twist Drills For Deel Hole DrillTaper Shank Twist DrillsTwist DrillsHandle Shank Drill Bit from Drill Bit Supplier or Manufacturer-Dongguan Koves Precision Tools Co Ltd. They will not locate accurately and the self-holding variety will not hold reliably if such problems.

A drill with oil hole that makes full use of state-of-the-art technology. They are designed to meet precise tolerance requirements and incorporate proprietary features that enhance durability and drilling speed while improving ease of use. Style Carbide Tip G.

But a drawing by Watt dated 1811 shows a tapered shank spade drill in a tapered spindle. It is the one that initiates the hole. The base metal high-speed steel is a material with metal components such as tungsten molybdenum and chrome added and has excellent abrasion resistance and toughness.

Our carbide-tipped drill bits are premium quality professional-grade tools manufactured in Germany to the highest industry standards for Simpson Strong-Tie. 122 rows Tapered squareround-shank drill bits have a tapered square shank that can be cut off to expose a round shank. Is known as a point.

The larger size drills are provided tapered shank. Features The original thinning shape 3-rake improves centripedality and chip separation. The shank is the end of a drill bit grasped by the chuck of a drill.

All the best Drill Drawing 35 collected on this page. Selling exclusively through authorized distributors in the US Canada and abroad Drillco offers a complete. A split point keeps the bit centered without a pilot hole.

The base metal high-speed steel is a material with metal components such as tungsten molybdenum and chrome added and has excellent abrasion resistance and toughness. Applications Capable of high efficiency machining of materials ranging from steel to stainless steel and aluminum. You can add up to 6 items per a category to the compare list.

Drill diameter cutting shank tapered Prior art date 1970-03-10 Legal status The legal status is an assumption and is not a legal conclusion. Morse had a competitor in the early years for both drill bits and the taper used for drill bits. Carbon adds to the strength of steel molybdenum increases flexibility and the combination of tungsten and cobalt allow tapered drill bits to work efficiently at higher temperatures.

It is held in the machine by chucks. The cutting edges of the drill bit contact the workpiece and are connected via the shaft with the shank which fits into the chuck. The draw-bar is important on milling machines as the transverse force component would otherwise cause the tool to wobble out of the taper.

And used to drill holes. The diameter increases by 0-3mm in lowest series having Morse taper shank No. Taper Shank Drill Bits HSS A taper shank drill high-speed steel is a cutting tool that is attached to a drill press a milling machine a lathe etc.

Grind away no more than absilutely necessary. The shank for these drills conforms to Morse tapers. Drillco About Us Family owned and operated since our inception in 1978 Drillco has been supplying industry with the finest selection of quality metal cutting tools manufactured in America and around the world for over 35 years.

1 by 0-25mm in lowest series shank number 2 and 3 by 0-5mm in Morse taper shank No. Drill Nomenclature-Points Elements of Drill Points Lip Relief Angle Varies with the diameter of the drill and hardness of the material On larger diameters and drills for harder materials lip relief is decreased to as low as 8 Drills for soft materials and small diameters have high relief angles up to 24 Lip relief angles are measured across the margin. Twisted V drill to support next generation high speed machining.

At times the female Morse Taper cavity in a machine may be slightly smaller than the maximum diameters shown above. In many cases a general-purpose arrangement is used such as a bit with cylindrical shaft and shank in a three-jaw chuck which grips a cylindrical shank tightly. The diameter varies from 15 to 26 mm increasing by 03 mm in lower series to 025 mm in higher series.

This is because the MT tooling often extends a bit past the end of the spindle that is receiving the Morse Taper Tool. Different shank and chuck. Point the front end of the bit at the wheel.

This was the Manhattan Fire-Arms Co. Drill Drawing For Fr. The drill shank taper is 1 in 6 and the drill is secured by a screw thread so the taper is there to provide good.

Swing the back end of the bit to the left between 5 and 10 degrees and lower the bsck end of the bit about the same. The point consists of the following major parts. For technical drawings and 3-D models click on a part number.

In essence it is the male end of the bit that does not drill or mill. The drawbar is then tightened drawing the shank firmly into the spindle. I would suggest you sharpen them by hand but very lightly.